Our production sites

Covering a total area of 10,000 m², the site handles the production of our wood/metal products, from receipt of the raw materials to shipment of the finished products. The site also includes a 2,000 m² outdoor showroom.

Wood serves as the primary raw material in the creation of our products, carefully chosen for their striking visual appeal and durability.

Scots pine

Hailing from Finland, our Scots Pine is renowned for its fine rings and exceptional uniformity due to its slow growth in this region's unique climate. This handpicked pine, free of sapwood, naturally falls into class 3 and requires no chemical treatment. After careful selection, the laminated planks are transported to our French plant. Upon arrival at our workshop, they are acclimatized to optimize their workability.

Accoya® wood

Derived from sustainable fast-growing woods via an acetylation process, Accoya® Wood emerges as a high-performance, eco-friendly material. With superior resistance to water and rot, it boasts FSC® and Cradle to Cradle Certified® Gold accreditations, alongside Material Health certification and a minimal carbon footprint. This exceptional wood, utilized in our lighting bollards and furniture, lends innovation, comfort, and enduring quality to our products, accentuating them with a unique touch.

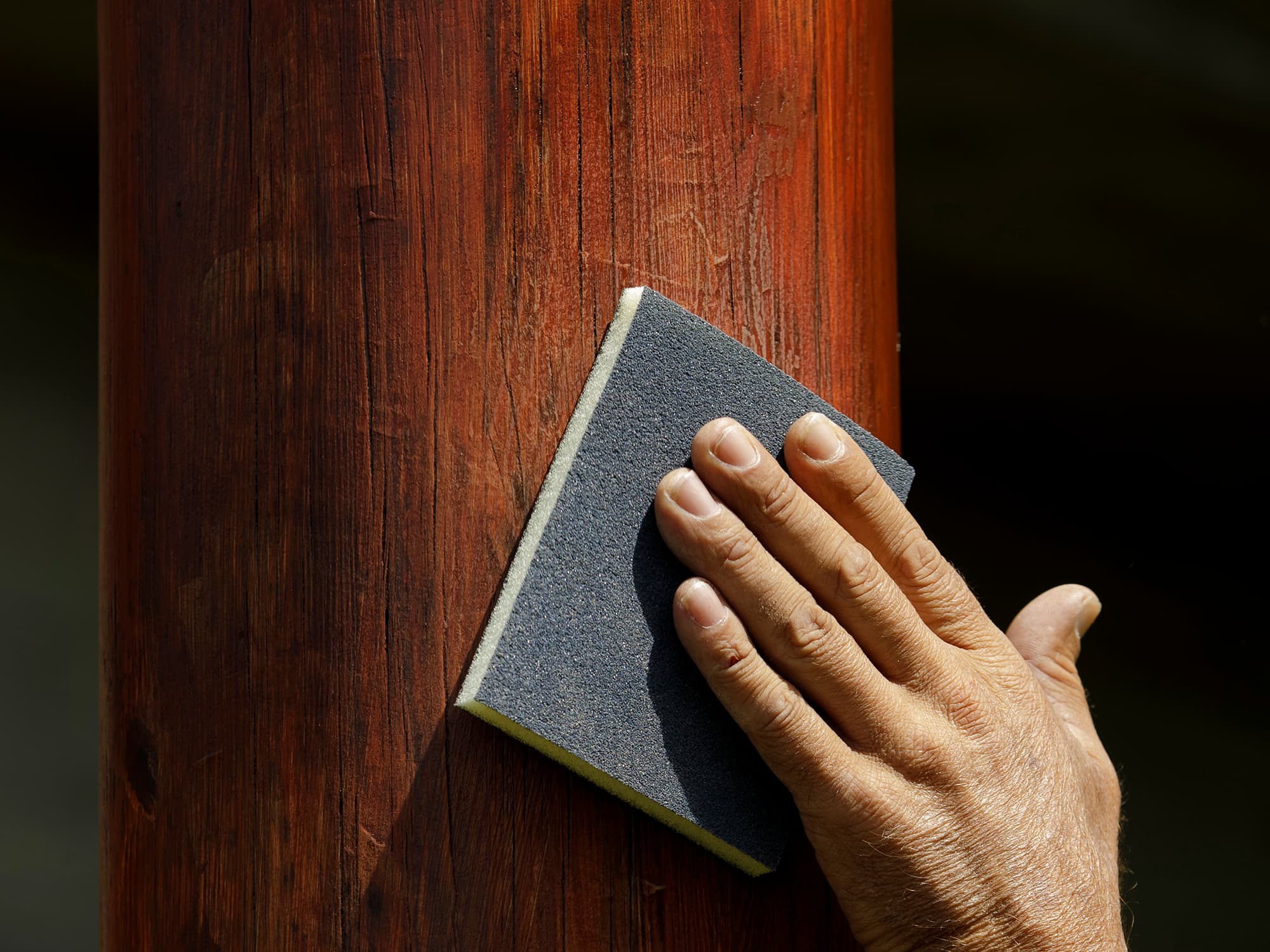

Beyond meeting our durability standards, wood brings a distinctive essence through its soft, noble, and warm characteristics, infusing each project with emotion. Its varied textures, hues, and light effects stand out as aesthetic advantages. During our furniture crafting process, a glaze-based finish is applied to shield the wood surface against external elements (UV rays, weather conditions, pests, etc.), ensuring long-lasting protection.

Furthermore, wood's ease of maintenance allows for effortless care and potential restoration to a like-new state if handled in accordance with our guidelines.

Utilizing our advanced HTE process, we have cultivated over 40 years of comprehensive expertise in manufacturing Glulam timber.

Our specially processed, glued laminated timber is tailored for outdoor applications, crafted into sleek lighting columns and stylish urban furniture pieces.

With superior mechanical strength, it is ideal for structures exceeding 10 meters in height, enabling expansive spans while effectively optimizing structural weight. This resource-efficient material boasts minimal scrap wastage during production, underscoring its sustainability and eco-friendliness.

Our products are manufactured and assembled in our workshops. The exceptional quality of the products that leave our factory is the outcome of a meticulously controlled industrial process paired with precision handiwork.

Once arrived in our workshop, the boards are left to rest while obtaining the best conditions for working with the wood.

Maintenance

Our glued laminated timber lighting columns are designed to support light sources. These columns are either internally designed by our team of designers or customized to meet the specifications of lighting designers or architects, playing a key role in enhancing the aesthetics of the installation site.

A quality structure must be maintained over time. The HTE manufacturing process developed by AUBRILAM is designed to guarantee the durability of our products and to optimise the durability of glulam for outdoor use. The HTE process includes a stain-based finish that colours and protects the surface of the wood. As it acts as a protective skin against external aggressions (UV, climatic conditions, termites, etc.), the stain must be maintained and cared on a regular basis.

The maintenance regimen we offer is simple to implement, allowing us to uphold the decorative charm of our products. Conducted on-site without the need for removal, this maintenance can be scheduled at various intervals during the product's lifespan. To assist our customers in this process, we provide AUBRILAM Care.

AUBRILAM Care expertise

With over 40 years of experience, our AUBRILAM Care service offers:

on-site diagnosis

tailored maintenance solutions featuring high-quality, time-tested products. Customized maintenance packages incorporating products that have proven their efficacy over the years

service carried out by trained and certified AUBRILAM Care personnel